Technology

|

|

|

|

|

Electrochemical Machining Electrode

(for Gas turbine air cooling hole)

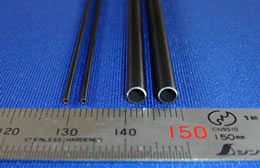

Providing ultra-fine pipes, Tokyo Titanium has manufactured extremely precise electrochemical machining electrodes

1. Specification

- Sizes : 0.8-4.3 dia. × 500~600L(extra fine pipe)

- Structure : Fluorocarbon resin is coated on outer surface of Ti-CP pipe

- Method : Electrochemical machining

- Electrolytic solution : Nitric acid aqueous solution

- Workpiece : Ni-Alloy Turbine Blade(casting)

- Elliptical pipes can be manufactured as well as round pipes.

- As for materials, not only Ti, but Ni-Ti, Inconel, hastelloy, Ta, Nb, Au, Ag, Pt and Zr can be utilized.

- The application of precise pipes is diverse such as for medical, food processing and electronic components.

2. Application

Gas Turbine blade air cooling hole

(Fine deep hole)

What's ECM

(Electrochemical machining)

ECM is a metal machining process involving the removal of material from a workpiece by means of electrochemical erosion. This process is achieved by passing a high current electrical charge from the positively charged workpiece through an electrolyte solution to the negatively charged cutting tool.

3. Requirement for Electrode Coating

Requirement

- Nitric acid resistance

- Insulation(pinhole-free)

- Coating thickness tolerance:±5μm

- Straightness:0.5mm/1,000mmH or less

Others

- Low friction

- Abrasion resistance

- adhesion(no spalling)

Application Range

- Outer surface of Ti Pipe

4. Process & Quality

Technique and Cost

- Rationalization of process

- Fine accurate piping

Quality

- We conduct a straightness test on all of our products, not a sampling test, in every process.