Competitive Edge

Tokyo Titanium, titanium specialists cluster,

provides the very best solution for you.

1. Coherent System

We are able to offer the best solutions from materials to titanium products.

Only a few companies are this comprehensively integrated!

2. Cost reduction by changing processing method (Reduction of material in use)

Our accumulated titanium engineering and expertise of over thirty years enable the reduction of material use, process time and cost.

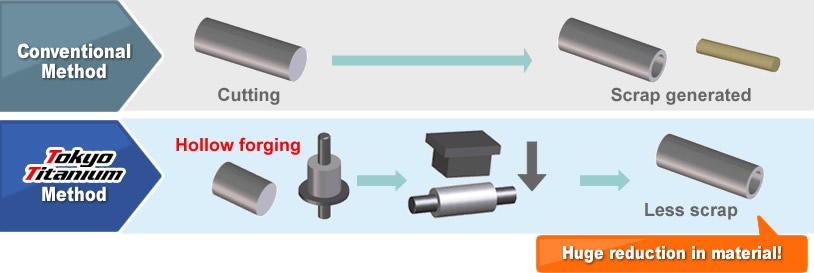

Example 1 Change from cutting to hollow forging

In the conventional method, titanium pipes have been manufactured by hollowing out the inside of a round bar, hence generating scraps as output. It is time-consuming and incurs a high cost for grinding.

However, Tokyo Titanium utilizes hollow forgings, which achieve a reduction in material use, and cut work time and its cost.

Material: Ti6AI-4V

For cutting from a round bar (unit:mm)

415dia × 491L 1P 297kg of material is necessary.

For hollow forging,

415OD × 343ID × 491L 1P only 95kg of material is required.

Example 2 Change from "cutting only" to "partial cutting and welding of pipe"

Tokyo Titanium has succeeded in reducing cost using our exclusive machining process and welding technology.

Material: Ti Class 2 (Ti-CP)

For cutting from a round bar

20dia × 120L 1P 0.18kg of material is necessary.

For our method (welding partially cut round bar and pipe)

12dia × 30L 1P 0.05kg of material

13.5OD × 12ID × 80L 1P 0.02kg of material

only 0.07kg of material in total is required.

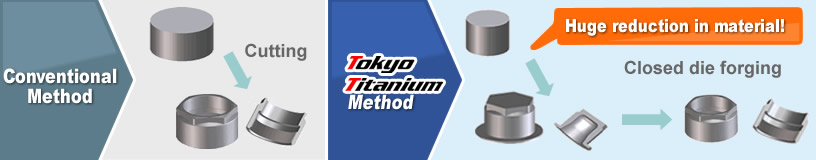

Example 3 Change from cutting to closed die forging

In the conventional method, a round bar is forged through cutting work.

Tokyo Titanium has adapted stamp forging and, as a result, succeeded in reducing material use, time and cost.

Raw materials: approx. 40% reduction

Process time: approx. 46% shortened

Price of product: 32% reduction

Material: Ti Class 2 (Ti-CP)

For cutting from a round bar

60dia × 35L 1P 0.68kg of material is necessary

For stamp forging

45dia × 58L 1P only 0.45kg of material is required.

3. Short lead time

Tokyo Titanium provides even small production lots using speedy procedures. We have previously shipped in one week after receiving the blueprint of the spool (pipe with flange).